Large Capital Construction

With most large construction projects there is often significant project completion and budget overruns. With many repeated issues eliminated if the owner ensured products were fabricated and installed the first time.

Currently, the engineering firm, fabricator and general contractor are being held accountable however more often than not each party is pointing at the other without assuming responsibility.

Projects that continue to be executed with the same issues does not appease the shareholders who are looking at the end of year balance sheets.

SHORES MDS can reduce errors caused by incorrect fabrication and installation through Dimensional Control industrial surveying.

It only takes the discovery of a couple of issues to payback the dimensional control contract value. After that it’s a service that makes the project money. This is something that very few services can actually definitely say.

| Task | Description | Reason |

| Project Layout | Check staked layout by the contractor prior to any excavation or concrete pour. | Prevents layouts from being set in the wrong location. |

| Foundation Verification | Check location and elevations of each foundation set. | SHORES MDS shall check anchor bolt locations, foundation center lines and elevations to ensure design conformity. |

| Existing Tie Point Verification | Verify each existing project tie point. | Ensures no engineering error when modeling

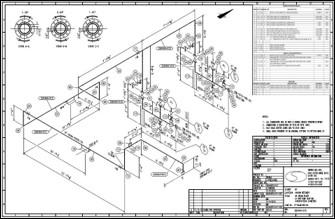

Design house models rarely show any flange deviance. SHORES MDS shall ensure that there are no significant bolt rotations, flange face errors and also that correct flange rating and diameter has been called out. |

| Cut Line and Hot Tap LocatingVerify each new tie point location.Cut lines are marked from known steel reference points. Generally, the steel is not square and errors are caused by incorrect cut lines being set.

SHORES MDS shall use the project coordinate system to locate cut lines. |

||

| New Tie Point Conformation | Verify each new tie point location. | Exact new tie point location shall be surveyed and coordinates confirmed.

This information will be communicated to Engineering to ensure that no modifications are required to be made due to any potential error. Flange deviances shall be reported to ensure pipe fabrication matches any alignment issues. |

| Equipment / Vessel As-Built | Verify each piece of equipment either at fabricator or at site laydown yard prior to installation. | Equipment and Vessels should be verified prior to install to ensure that each item has been fabricated per design drawings.

SHORES MDS have found in the past incorrect nozzle placement, incorrect nozzle diameters, incorrect nozzle ratings and vessel centerline alignment errors. |

| Structural Alignment | Erected steel should be verified for elevation conformity and straightness. | Issues have been caused by beams being installed at incorrect elevations. This error causes pipe bust and other major project rework. |

|

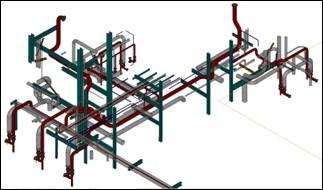

Pipe Fabrication QC |

Spool fabrication errors cause significant negative impacts to project schedules and budgets. |

SHORES MDS shall inspect spools prior attempted installation to ensure dimensional accuracy. |

|

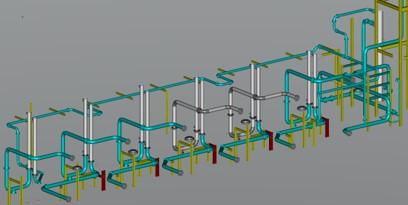

Hook Up Spool Survey |

Remove the need for field welds on any spool that interfaces with flanged nozzle connections. |

Any spool that interfaces between a piece of equipment and pipe rack should be surveyed. Surveying the closing spool removes any stresses that are applied to nozzles through incorrect pipe fabrication. |

|

Tower Alignment |

Alignment QC on towers to ensure towers are set vertically within acceptable tolerances. |

SHORES MDS shall perform final verification on tower alignment to ensure that the tower has been set to within verticality code. |

| Safety |

Reduction in heavy lifts, field welds and rework. |

SHORES MDS shall ensure that multiple handling of components is reduced by prefabrication complete components and removal of significant dimensional busts. |

|

Project Disputes |

Clarify if Engineering, Fabrication or Installation was responsible for error. |

SHORES MDS shall survey disputed item to verify what actually caused the rework. |

Piping all prefabricated prior to downcomers and pumps being installed. Existing tie points were surveyed, downcomers and pumps were surveyed in a laydown yard, piping drawing dimensions revised and piping surveyed post-fabrication. All piping installed free from any error.